Carpark ventilation can often involve a vast and complicated network of extract and/or fresh air ducting. Where space is limited due to low ceiling levels, structural elements, piped services and cable trays. There is often little room for ducting. How can we reduce the extent and size of the ducting required?

The current compliance standard for carpark ventilation prescribes a design based on multiple factors, including usage factor (residential/commercial), Vehicle Type (Diesel, petrol, electric) and staff exposure. The calculation also involves parameters of the carpark layout itself such as the average distance a car might travel, location of relief openings, and extract locations.

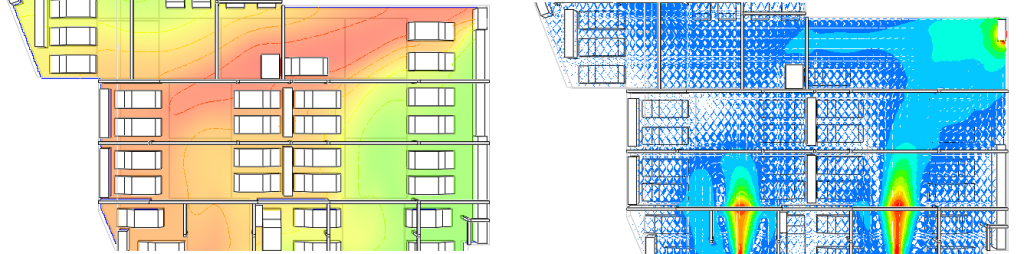

Experience shows that this can result in larger flowrates, large duct sizes and excessive duct lengths. An alternative method is to use a performance-based solution. This approach allows for flexibility of design by outlining the requirement of carbon monoxide concentration limits. This is what is assessed through Computational Fluid Dynamics, also known as CFD.

MEPS recently conducted a CFD analysis on a 1,900m² basement carpark with one entrance/exit door. Using the prescriptive pathway this would have potentially resulted in excess of 50 meters of ducting and a flowrate of at least 4750L/s. However, our CFD analysis showed that this can be reduced to 3000L/s at a single localised extract grille with no additional ducting. Then just three jet fans are spaced throughout the carpark to circulate air. This not only saves upfront installation costs, but also running and maintenance costs over the lifetime of the system!

CFD results can also provide Natural ventilation options not covered by the Acceptable solutions.

If you are facing the reality of an expensive carpark ventilation system and want to look into an alternative design, CFD could be your solution!