It seems to be more frequent that tender tags excluding construction shop drawings are being often accepted without understanding the full implications. Although this may provide an upfront savings to the client, it can result in greater costs to the client and the contractors both during construction and over the lifetime of the building. More critically it often causes delays in building.

So what are shop drawings, and why are they so important?

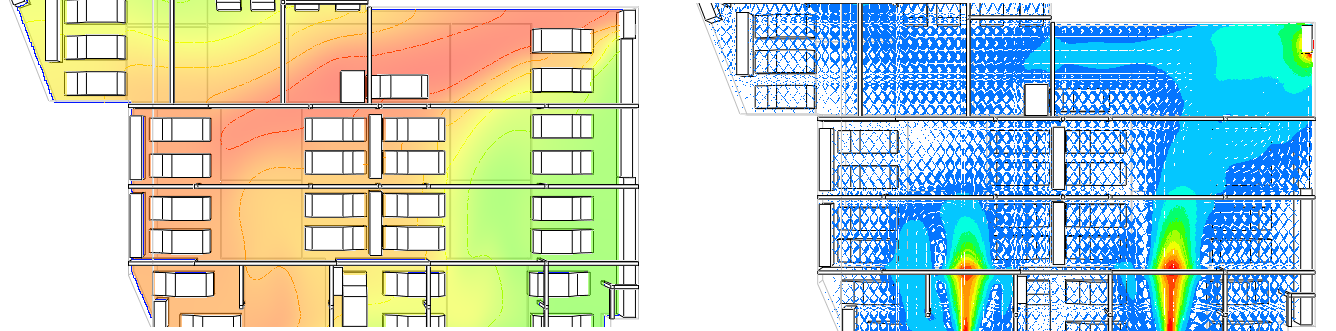

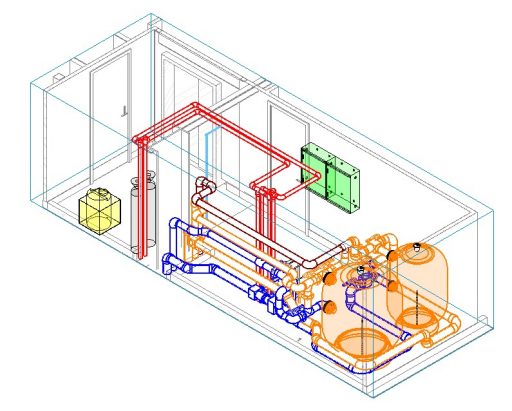

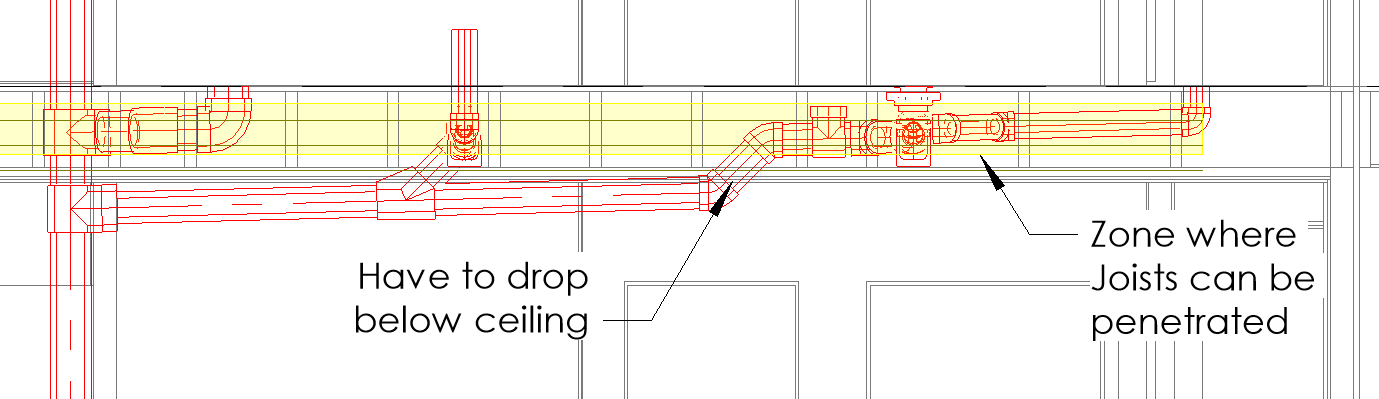

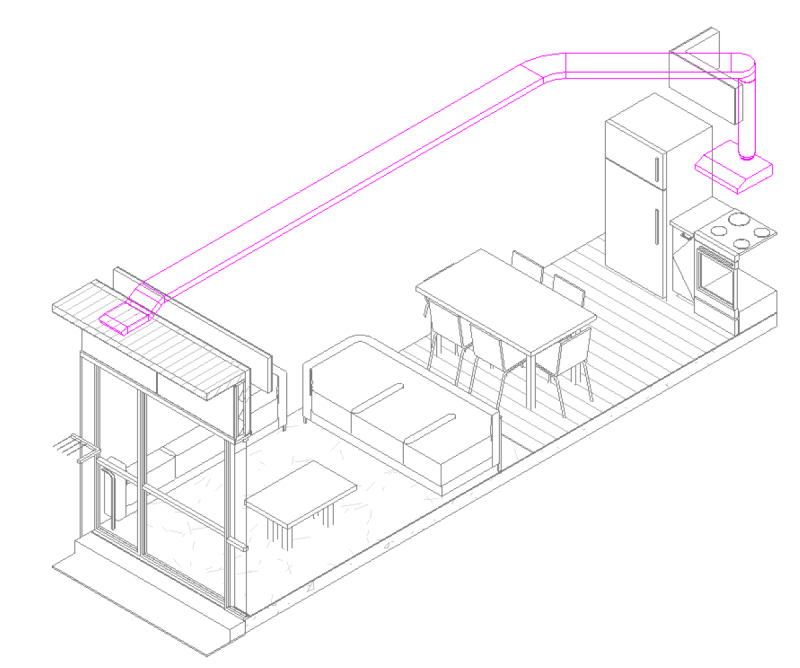

Design drawings from the engineer are not fully detailed even when done in 3D. They are intended to provide the necessary information for contractors to price a code compliant system in accordance with the clients’ requirements. The are also coordinated with information available at the time of design. Shop drawings are an extension of the drawings with additional details such as specific equipment and product selections, dimensioned layouts, details for fabrication, seismic restraints, equipment supports and are fully coordinated with other trades.

During design it is difficult to account for the trade prices, lead times, each contractor’s familiarity of all the various products and equipment, and therefore performance specification are provided for the contractor to meet. In most cases, there are multiple suppliers who can provide an acceptable product leaving the option open for the contractor to provide competitive pricing, and therefore savings for the client. Many Clients also require the Tenders to be “open” and not show any favoritism or mention any specific brands.

However, not all equipment options can be simply placed onto the drawings without design revisions which is where shop drawing come in to capture the adjustments.

The contractor may also see opportunities for ease of installation and/or value engineering. By proposing these revisions during the shop drawing phase, these opportunities can be assessed by the consultant engineer for compliance and performance implications. In some cases, these value engineering opportunities may not be acceptable, and it is far simpler and cheaper for them to be declined at the shop drawing phase rather than to be remediated when discovered during a site visit after it has been installed. Although an alternative proposal by the contractor may be code compliant, it may compromise other specific client requirements they are unaware of.

The production of shop drawings gives the all parties confidence that all involved have read and understood the intent and specifics of the design drawings and specifications. It is not uncommon for specifications or even drawings to go unread, and a non-compliant installation to be discovered on site. This can cause headaches for everyone involved and can sometimes lead to unfavorable compromises in the face of construction timeline implications.